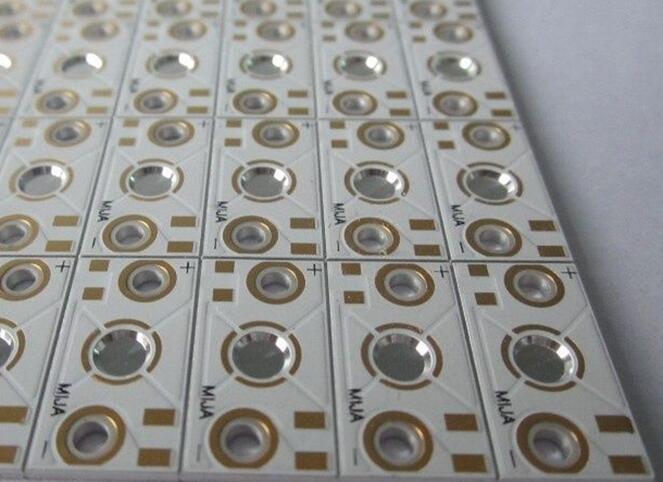

Double sided PCB aluminum plate has excellent thermal conductivity and mechanical properties. In the circuit design scheme, the thermal diffusion is effectively treated, so as to reduce the operating temperature of the module, prolong the service life, and improve the power density and reliability.

The so-called aluminum substrate refers to the purpose of heat dissipation. The base material is made of the structure of resin, glass fiber and copper metal, and is added to the design of aluminum plate. Its purpose is to combine aluminum plate and circuit board to reduce the operating temperature of the product by using the light weight and good heat transfer characteristics of aluminum. So, single, double or multi-layer circuit boards are used, It depends on the copper lines, which are called him on several levels

Generally, considering the cost and technical performance, aluminum plate is an ideal choice. The aluminum plate available for selection is 606150521060, etc. If there are higher requirements for heat conduction, mechanical, electrical and other special properties, copper plate, stainless steel plate, iron plate and silicon steel plate can be used.