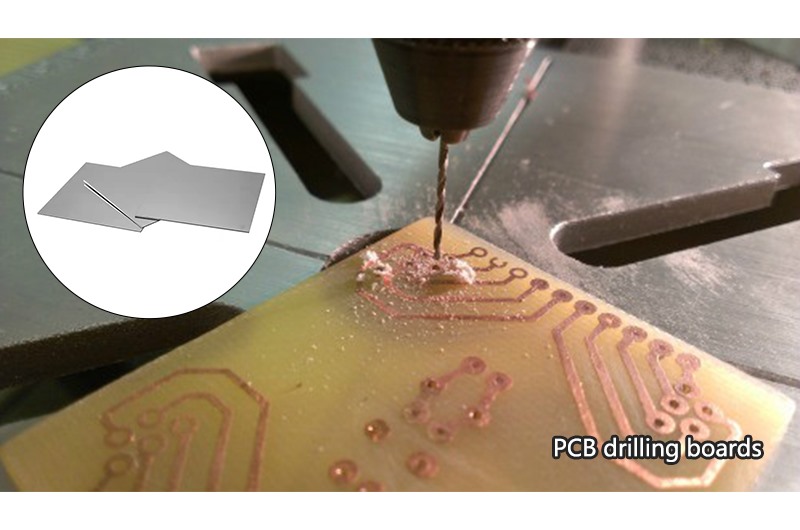

The conventional aluminum sheet is used as the PCB drilling boards and matched with different types of backing plates. Among them, the nail head, hole thickness, and wick of the PCB board with high heat dissipation lubrication backing board are much lower than others. The analysis is mainly due to the use of high heat dissipation lubricating backing board The drilling temperature is much lower than others; the conventional wood fiber board is used as the backing plate, and different types of PCB drilling boardss are used. Among them, the nail head, hole thickness and wick of the aluminum PCB board are slightly lower when using ordinary MVC, and the use of heat dissipation Type MVC, Mitsubishi Gas MVC, PCB board nail head, thick hole, lamp

The core will be much lower. The analysis is mainly due to the much lower drilling temperature of the heat-dissipating MVC and Mitsubishi MVC MVC; the heat dissipation of the PCB drilling boards is related to the heat dissipation of the resin film. Use this kind of PCB drilling boards with high heat dissipation characteristics , The drill bit is not easy to adhere to the amount of drilling chips, and chip removal will be easier; at the same time, the heat dissipation resin glue will melt into a lubricant at high temperatures to further promote chip removal. Chip removal directly affects the nail head, hole thickness, and thickness of the PCB board. The quality of the hole wall such as the wick is the reason why the heat dissipation of the PCB drilling boards will affect the quality of the hole wall. The verification result is consistent with the data content of Mitsubishi Gas in Japan and LCOA in the United States.