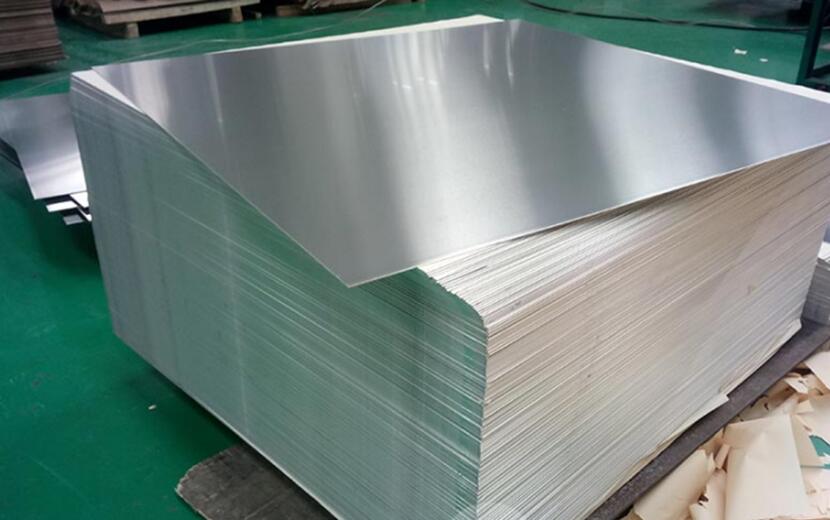

Under normal circumstances, considering the cost and technical performance, aluminum plate is an ideal choice. Available aluminum drill entry sheet are 6061, 5052, 1060, etc. If there are higher thermal conductivity, mechanical properties, electrical properties and other special performance requirements, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

Commonly used in LED lighting products, there are two sides, the white side is soldered with LED pins, and the other side presents the natural color of aluminum. Generally, the thermal conductive paste is applied to contact the thermal conductive part. Mainly used in LED lamps and audio equipment, power supply equipment, etc., the main advantages are fast heat conduction and good heat dissipation performance.

Compared with the traditional FR-4, the aluminum drill entry sheet can minimize the thermal resistance, so that the aluminum drill entry sheet has excellent thermal conductivity; compared with the ceramic substrate, its mechanical properties are extremely good.

In addition to good heat dissipation performance, aluminum drill entry sheet also have the following advantages:

Comply with RoHS environmental protection requirements

More suitable for SMT process

Higher current carrying capacity

Extremely effective treatment of thermal diffusion in the circuit design scheme, thereby reducing the operating temperature of the module, prolonging the service life, and improving the power density and reliability;

Reduce the assembly of heat sinks and other hardware (including thermal interface materials), reduce product volume, and reduce hardware and assembly costs; optimize the combination of power circuits and control circuits;

Replace fragile ceramic substrates to obtain better mechanical durability.

Compared with the ordinary FR-4 sheet, the aluminum drill entry sheet has the biggest advantage that it can carry higher current. Like FR-4, the circuit layer uses copper foil as the wire for connection. Compared with the traditional FR-4, the aluminum drill entry sheet can carry higher current with the same thickness and the same line width.