Although LED has many advantages, it still faces some challenges. The two main problems are the improvement of luminous efficiency and heat dissipation. Among different metal substrates, copper is the substrate with the best heat dissipation effect, and its thermal conductivity is higher than other metal substrates. Due to the high density, high price, easy oxidation and inconsistency of copper materials, the substrate material has a trend of lightweight development, so it has not been widely used.

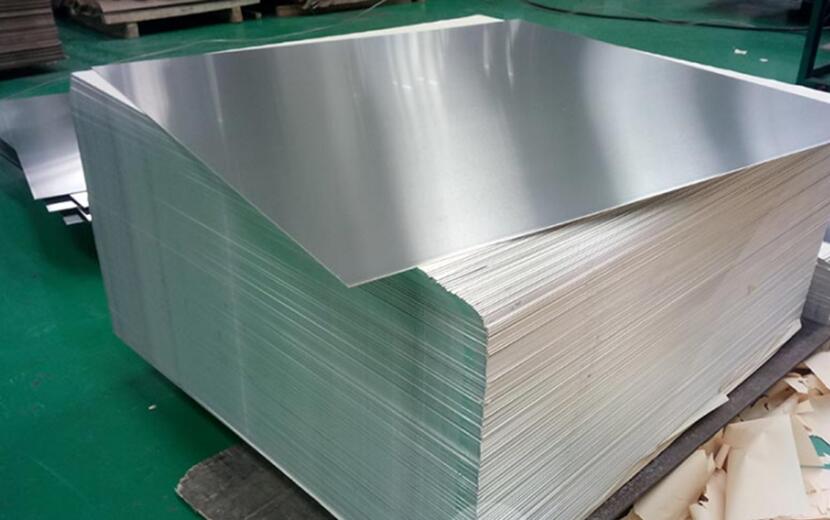

Although the heat dissipation of the printed circuit boards entry sheet is worse than that of the copper plate, it is much better than that of the steel plate. It has the characteristics of low density, light weight, oxidation resistance, and low price. Therefore, it is the most widely used and most used composite board among metal-based copper clad laminates. , The purity can reach more than 99.00%, and does not contain other alloying elements. The relatively cheap 1000 series is the most commonly used series. The standard FR-4 printed circuit board has a poor heat dissipation effect and cannot effectively dissipate the heat of the LED.

The printed circuit boards entry sheet made of it can prevent the working temperature of the components and the substrate loaded on the PCB from rising, and can quickly dissipate the heat generated by the power amplifier components, large circuit power switches and other components.