The

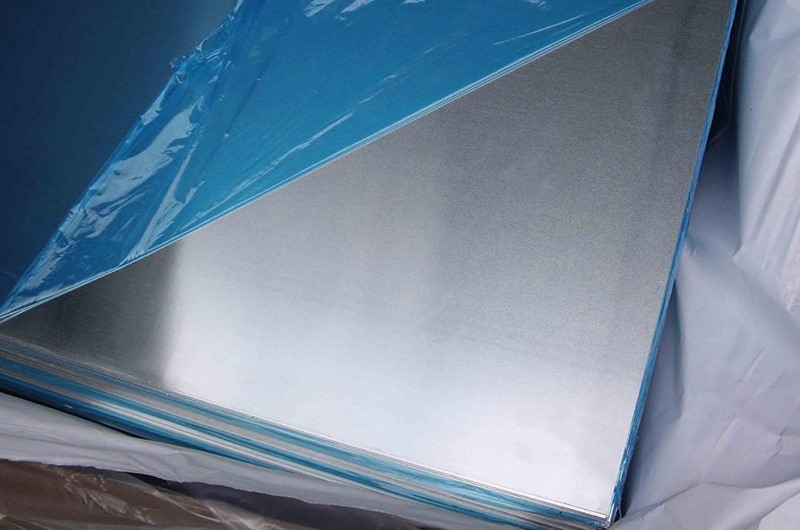

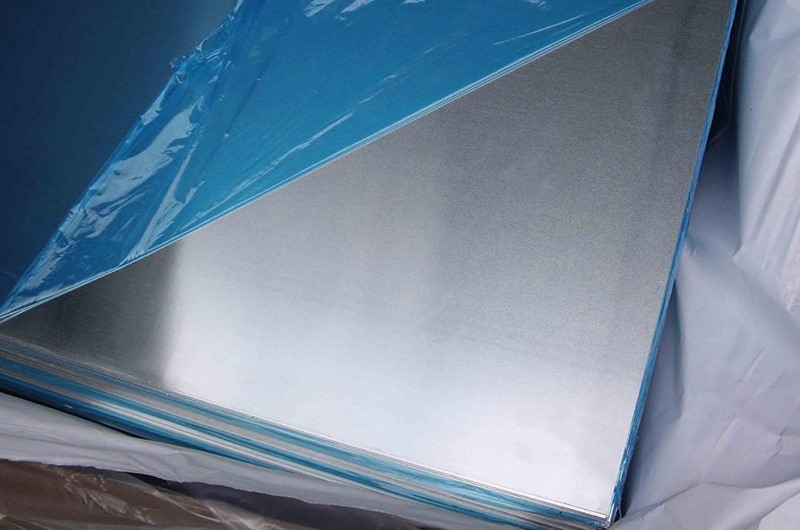

1100 aluminum drilling entry sheet is a key material required for drilling the printed circuit board (PCB for short). The early function of the

1100 aluminum drilling entry sheet is relatively simple, but it simply suppresses the front and improves the drilling accuracy. In recent years, with the vigorous development of the PCB industry, it has been learned from the introduction that Mitsubishi Gas in Japan and LCOA in the United States have put forward the concept of heat dissipation in the development of the

1100 aluminum drilling entry sheet, and the

1100 aluminum drilling entry sheet is given a new heat dissipation function. The data shows that the cover The heat dissipation function of the backing plate is conducive to improving the reliability of the PCB board. In the PCB industry, improving the reliability of drilling is a problem that the industry has been facing and needs to overcome. PCB factories improve the reliability of drilling from different angles. The conventional methods are: select suitable copper clad laminate materials (preferably large companies, CAF resistant Higher grade materials), optimize drilling parameters (reduce the number of stacks, reduce the number of drill holes, reduce the number of drill pins, etc.), and use appropriate de-glue and electroplating process parameters. In addition, this article will discuss the feasibility of improving PCB reliability from the perspective of

1100 aluminum drilling entry sheet heat dissipation.

The Japanese Mitsubishi Gas data book shows that the heat dissipation effect of the

1100 aluminum drilling entry sheet is conducive to improving the reliability of the PCB board (improving the roughness of the hole wall); the American LCOA data book shows that the heat dissipation effect of the backing plate is conducive to improving the reliability of the PCB board ( Lower the wick). Use conventional aluminum sheet as the 1100

aluminum drilling entry sheet, match different types of backing plates, use conventional wood fiber board as the backing plate, match different types of 1100 aluminum drilling entry sheets, and use the above-developed drilling heat dissipation test evaluation method to test the drilling temperature of various cover backing plate combinations At the same time, the PCB board after drilling will be polished, coppered, and electroplated according to the normal process and normal process conditions. After completion, sample and test the nail head, hole thickness, and wick, and analyze the drilling temperature and nail The relationship between the head, hole thickness, and wick determines the feasibility of realizing auxiliary drilling for heat dissipation of the 1100 aluminum drilling entry sheet to improve PCB reliability.