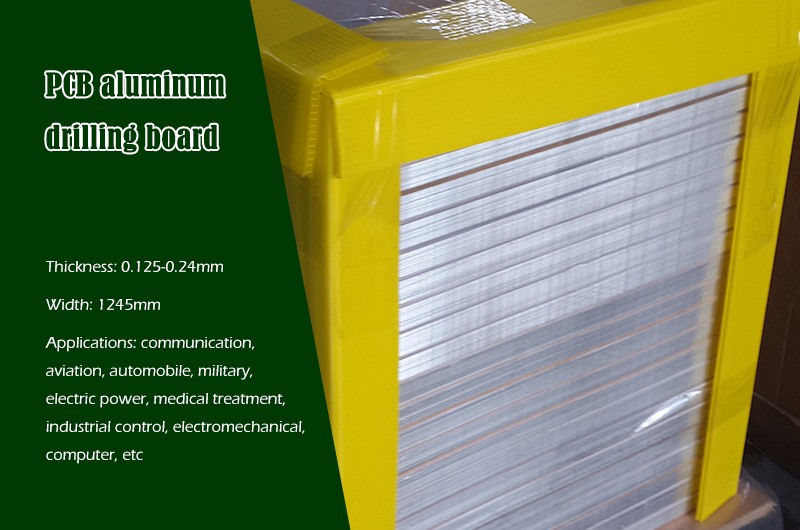

PCB aluminum drilling board

The use of aluminum sheet for circuit board drilling has the following advantages:

1. The aluminum sheet effectively prevents the drill tip from producing indentations and scratches on the surface of the copper clad laminate during processing.

2. It can provide positioning and guiding function during the downward process of the drill bit to improve the positioning accuracy of drilling.

3. The aluminum sheet has an excellent thermal conductivity function, which can quickly dissipate the heat generated by friction when the drill bit is drilled at high speed, effectively prevent the bit from overheating, thereby improving the life of the bit and better hole wall condition.

4. The aluminum gasket prevents burrs from being produced on the surface of the film copper foil board during high-speed drilling.

The commonly used aluminum alloys for aluminum gaskets are 1100 coils, 1060 aluminum coils, and 3003 aluminum plates. The aluminum content is more than 99%. The state is mainly H18. The common thickness is 0.125-0.24mm, and the coil width is about 600mm. With a width of 1244/1245mm, aluminum gaskets are widely used in various fields such as communications, aviation, automobiles, military, electric power, medical treatment, industrial control, electromechanical, and computers.