The aluminum-based PCB board has excellent heat dissipation performance, and the printed board assembly assembled by it can dissipate heat in time during the working process, so as to avoid the device heating up and affecting the equipment work.

b) Good machinability

The aluminum-based PCB board has high mechanical strength and toughness, which can realize the manufacture of large-area PCB, and can install heavy components. At present, the thickness of the aluminum substrate available in the market can reach 3.2mm, and some power supply development units have combined the circuit board and the mounting base.

c) Electromagnetic shielding

The aluminum-based PCB board has a good shielding function, which can prevent the radiation and interference of electromagnetic waves and ensure the normal operation of the electronic circuit.

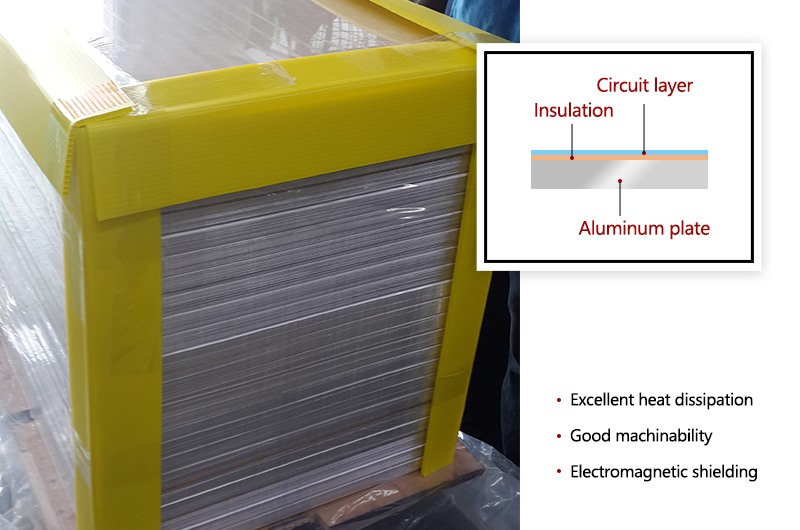

Structure and properties of aluminum entry sheet PCB

The aluminum-based printed circuit board is a composite printed circuit board with a metal substrate, a dielectric layer and a printed wire. It consists of a metal base layer, a thermally conductive insulating layer, and a conductive layer.

a) Circuit layer: It is equivalent to the copper clad layer of ordinary PCB, and the thickness of circuit copper foil is generally 35-75 μm.

b) Insulating layer: The insulating layer is a layer of low thermal resistance thermally conductive insulating material with a thickness of 0.07-0.30 mm. Different manufacturers use different materials and processes to ensure insulation strength and thermal conductivity, which is the core technology of metal-based copper clad laminates.

c) Base layer: This is the metal substrate, usually aluminum or copper.

Due to the mismatch of expansion coefficients, there are great limitations in high-reliability electrical equipment, so necessary stress relief measures must be taken during use. In particular, attention must be paid to the use temperature and environmental conditions of the product. Under the alternating temperature conditions, the reliability of the product needs to be re-evaluated. Taking measures to relieve stress in the process can improve the stress of components and solder joints to a certain extent, and improve the reliability of electronic products.

Application of aluminum entry sheet PCB

Due to its various excellent properties, aluminum substrates are widely used in industrial equipment, power equipment and other fields, especially in LED lighting engineering.